INDUSTRY-LEADING FEATURES

Title

FUME EXTRACTION - CLEAN AIR

XY TOOLHEAD - AUTO ALIGNMENT

BUILT-IN AUTOMATIC FILAMENT DRYING SYSTEM

AUTO SHUTDOWN AND SAFETY SYSTEMS

BUILT FROM STEEL

MADE USING TOP-OF-THE-LINE COMPONENTS

Title

LINEAR RAILS

Linear-Rail Motion System

TRIPLE MOTOR Z-AXIS

True Self-Leveling Build Platform

NON-PLANAR READY

6 Independent Axis and 5 Degrees of Freedom

CUTTING-EDGE MOTION SYSTEM

A TOTALLY UNIQUE, QUAD-MOTOR X/Y-AXIS, TRIPLE-MOTOR Z-AXIS

Title

Solid Steel Frame

Terminal Block Connections

4-Point Build Plate Mounts

Kinematic Z-Axis Mounts

Easy-Access Belt Adjustment

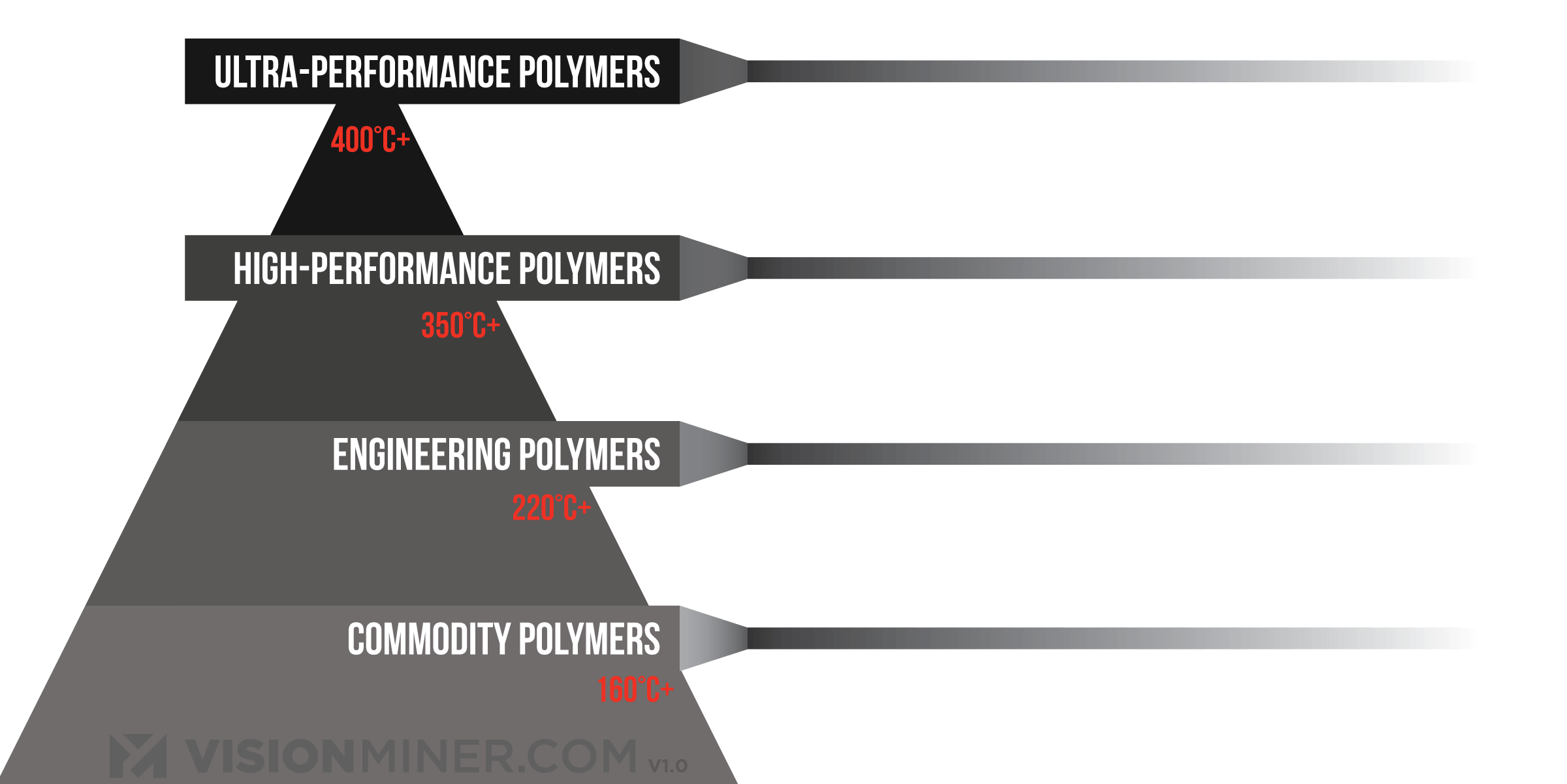

MADE FOR ENGINEERING MATERIALS

USE THE WIDEST RANGE OF PERFORMANCE THERMOPLASTICS

Title

WHAT FILAMENTS CAN YOU PRINT ON THE 22 IDEX?

POLYMER CLASS

AMORPHOUS

SEMI-CRYSTALLINE

ULTRA-PERFORMANCE POLYMERS

400ºC+

HIGH-PERFORMANCE POLYMERS

330ºC+

ENGINEERING-GRADE POLYMERS

220ºC+

COMMODITY-GRADE POLYMERS

180ºC+

INDUSTRY-PROVEN TECH

MADE USING CUTTING-EDGE PARTS

Title

SLICE ENGINEERING COPPERHEAD

Thermally Consistent Heat Blocks and Bimetallic Heat Breaks

BONDTECH LGX PRO EXTRUDER

Industry proven, tested, and used worldwide

PRE-CONFIGURED SLICER PROFILES, OR USE YOUR OWN

PrusaSlicer, along with the Duet 3 web interface means: your computer will work, as-is.

PARTNERED WITH THE BEST IN THE INDUSTRY

DETAILED SPECIFICATIONS

Title

My Wishlist

Wishlist is empty.

Compare

Shopping cart