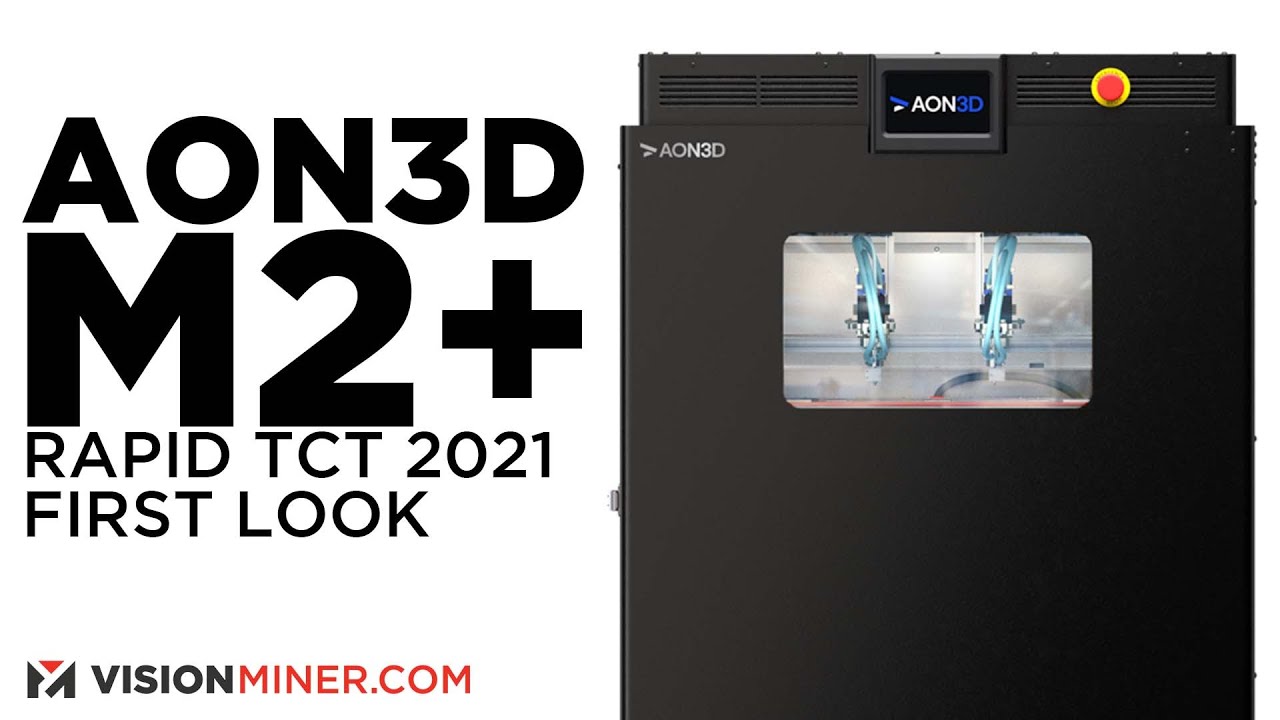

M2+

LARGE VOLUME, HIGH-TEMPERATURE

The AON-M2 is a high temperature, industrial 3D printer that can fabricate the highest performance thermoplastics. Print bigger and better with its actively heated build chamber and large build volume.

HIGH-TEMPERATURE

OPEN MATERIAL SYSTEM

500ºC Nozzles

200ºC Buildplate

135ºC+ Chamber

450 x 450 x 565mm Build Volume

IDEX Dual-Extrusion

200ºC Buildplate

135ºC+ Chamber

450 x 450 x 565mm Build Volume

IDEX Dual-Extrusion

INDUSTRIAL 3D PRINTING

MADE ACCESSIBLE

Affordable hardware and materials plus the largest build volume in its class make AON3D’s additive manufacturing platform accessible to businesses of all sizes.

3D Print PEEK, PEKK, ULTEM™, Carbon fiber and glass fiber composites, and affordable prototyping materials.

Affordable hardware and materials plus the largest build volume in its class make AON3D’s additive manufacturing platform accessible to businesses of all sizes.

NEXT-LEVEL SUPPORT

AON3D is more than just a hardware provider - you get to tap into their team of materials engineers, polymer focused PhD's, and application consultants to help you successfully complete your projects.

High Performance Materials

Designed to print aerospace-grade thermoplastics, including PEEK, PEKK, Ultem™, carbon fiber filled variants, and many more.

135ºC Chamber Temperature

High build chamber and bed temperatures are crucial for ensuring first layer adhesion, preventing warping and improving interlayer bonding.

Build Bigger & Make More

The 18" x 18" x 25" build envelope allows you to print bigger, or run batch jobs of multiple parts at once.

Liquid-Cooled Precision

The stepper motors and both hot ends are cooled with a liquid cooling loop, which extends component lifetimes and offers accurate control over the melt-zone while extruding.

Double the Design Opportunities

Dual independent toolheads allow you to design parts using multiple materials, such as soluble supports, or quickly switch between two different nozzle sizes.

Dedicated Expert Support

Expert materials and engineering support come with every machine, including on-site training with each 3D printer delivery.

Easy Remote Management

Remotely manage your print queue and machine from any device on the same network. No software installation required.

Detailed Specifications

Printing Technology

Fused Filament Fabrication, or Fused Deposition Modeling (FFF, FDM)

Build Volume

450 x 450 x 565 mm

18 x 18 x 22.8 in

Build Platform Material

Vacuum Bed for Swappable Build Surfaces

PC & PEI sheets

Carbon Fiber PEEK sheet

Material-Specific Build Sheets

Build Platform Leveling

Adaptive mesh leveling

Tool Heads

Dual, fully independent

Layer Resolution

0.005” (125 micron, all Axis, real-world application)

50-500 Micron Standard Layers

Speeds

Travel Speed: 500mm/s

Printing speeds depend on material

Filament Diameter

Standard 1.75mm Filament

Open Material System

Nozzle Diameter

Hardened Steel: 0.2,0.3,0.4,0.6,0.8, 1.0, 1.2 mm

Position Accuracy

XY: 25 μm Z: 1 μm

Regulatory Compliance

CE, CSA/UL available upon request

Warranty

AON3D Warranty

Extruder Temperature

500°C+

Build Plate Temperature

200°C

Chamber Temperature

135°C

Forced Convective Air Flow

A thermal optimized, precision-controlled build chamber ensures static printing temperatures.

Input File Type

Standard G-code, Marlin based

Wifi Remote Access

Power Consumption

208-240 VAC, 50/60Hz,

single phase L6-20 outlet, European adapter available

110/120v outlet for vacuum pump

Machine Dimensions

Machine Dimensions:

945 x 806 x 1440 mm

Recommended Footprint:

2000 x 2000 x 3000 mm

Installation Size:

1150x955x1450mm

Shipping Weight & Dimensions

43 x 46 x 63 inches

870lbs

Materials

Any 1.75mm Filament, including: ABS, ASA, Nylon (PA66, PA6, PA12), PC,PEEK, PEKK, PETG, PSU, PPSU, TPC, TPU, ULTEM™Carbon fiber and glass-filled variants of the above + Various soluble and break-away support materials, Open Material System

10x Better Economics

Affordable industrial 3D printing is finally here. The AON-M2 unlocks the innovative power of additive manufacturing, at a fraction of the cost.

Open Materials System

Avoid getting tied down with costly proprietary polymers, and experience the freedom of choosing between leading chemical companies.

Aerospace-Grade Thermoplastics

Choose from materials that can replace metals, with properties that can withstand the harshest operating conditions.

AON M2+

STARTING AT

$59,400

MSRP plus around $10-20k

of required accessories

Call or email sales@visionminer.com

for a detailed quote

My Wishlist

Wishlist is empty.

Compare

Shopping cart