Description

[custom_html]

3DXSTAT™ ESD PEI [Polyether Imide] is made using ULTEM™ 1010 resin and multi-wall CNTs. ULTEM™ 1010 is an amorphous, ultra polymer that combines excellent mechanical, thermal, and chemical resistance properties. The addition of carbon nanotubes is an efficient and effect way to achieve consistent and reliable electrostatic protection.

[/custom_html]

3DXSTAT™ ESD PEI Made Using ULTEM™ 1010 3D Printing Filament

3DXTECH produces this 3D printing filament using a specialty compound custom-formulated using ULTEM™ 1010 PEI resin and advanced carbon additives. PEI is an amorphous, high-performance polymer that combines excellent mechanical, thermal, and chemical resistance properties.

Our PEI based filaments offer the ability to create parts with excellent properties at elevated temperatures due to a very high glass transition temperature (Tg). Ideal for use in critical applications which require electrostatic discharge (ESD) protection, a high level of cleanliness, and the outstanding thermal and chemical properties you’ve come to expect with PEI based compounds.

Benefits of PEI Include:

- High thermal properties

- Inherently flame resistant and self-extinguishing

- Long-term hydrolytic stability

- Excellent dimensional stability, low heat creep sensitivity, and a very low, uniform coefficient of thermal expansion create highly reproducible part-to-part dimensions

- Exceptional strength and modulus, even at elevated temperatures

- Good resistance to a broad range of chemicals, include automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions

Benefits of 3DXSTAT™ Include

- Consistent surface resistivity

- Improved retention of impact & elongation

- Low particulate contamination

- Minimal contribution to outgassing and ionic contamination

Typical ESD PEI Applications Include:

- Semi-con: HDD Components, Wafer Handling, Jigs, Casings, & Connectors

- Industrial: Conveying, Metering, and Sensing Applications

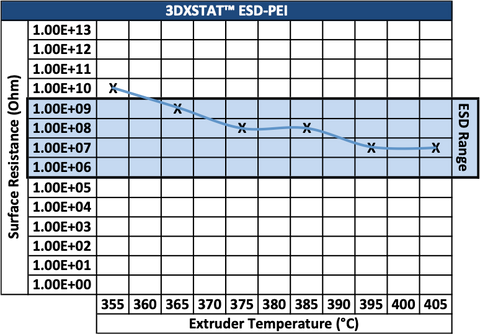

Target Conductivity for 3DXSTAT ESD PEI:

- 10^7 to 10^9 ohm surface resistivity on 3DP sample using concentric ring test method.

- Note: Internal studies have indicated that increased extruder temperatures can achieve higher levels of conductivity. Likewise, lower extruder temperatures have resulted in lower levels of conductivity. Each printer is set-up differently, not to mention varied part geometry. Therefore, expect some trial time to understand how ESD PEI filament works in your specific printer and application.

Surface Conductivity as a Function of Extruder Temperature:

The surface resistance of the printed ESD PEI part will vary depending on the printer’s extruder temperature. For example, if your testing indicates the part is too insulative, then increasing the extruder temperature will result in improved conductivity. Therefore, the surface resistance can be ‘dialed-in’ by adjusting the extruder temperature up or down depending on the reading you receive on your part.

Filament Specifications:

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 360-390°C

- Bed Temp: 140-160°C

- Bed Prep: Nano Polymer Adhesive gives us the best results

- Heated Chamber: Recommended, a chamber helps reduce warping and improves layer adhesion

- Supports: ThermaX™ HTS High-Temp Support or Aquasys 180 works ideal for complex, high-temp materials like this

- Drying Instructions: 120°C for 4 hours

Annealing 3D Printed Parts:

If needed, parts printed using PEI may be annealed in a hot-air oven to reduce any printed-in stresses which may be present inside the part. Printed-in stresses may occur in any plastic and may result in lower than expected mechanical properties. If this is an issue with your part, you can follow the simple 5-step ramp up/down process for annealing the PEI parts.

- Step 1: Place printed parts in cool, room-temp oven.

- Step 2: Set temp to 300°F and allow to stabilize for 1 hour.

- Step 3: After 1 hour at 300°F, increase oven temp to 400°F and allow to stabilize 1 additional hour.

- Step 4: After 1 hour at 400°F, reduce heat back to 300°F and allow to stabilize for 30 minutes.

- Step 5: After 30 minutes, turn off oven heat and allow printed parts to return to room temp inside the oven as it cools.

ULTEM™ is a registered trademark of Sabic Innovative Plastics.

3DXTECH manufactures this filament using a custom-formulated ESD-safe compound made using ULTEM™ PEI resin.

Additional Information

My Wishlist

Wishlist is empty.

Compare

Shopping cart