3D Printing Solutions, a partner of INTAMSYS in Australia, published a study on ways to achieve warp-free 3D printed polycarbonate parts this week.

It's great to see comparison studies like this beginning to pop up -- it really shows the quality and advantages of the Funmat HT and INTAMSYS printers.

The study covers:

- Causes of warping that are widely observed in polycarbonate 3D printing.

- Ways to minimize internal stress or warping during printing.

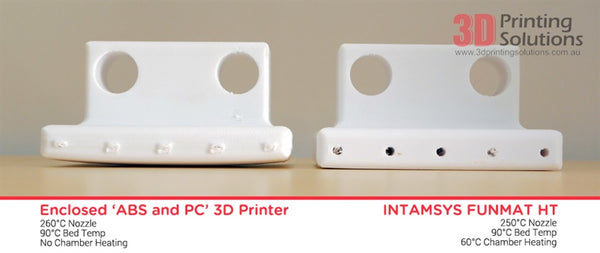

- Detailed comparison of parts with and without an active heating chamber.

HOW DO WE MINIMIZE INTERNAL STRESS / WARPING DURING PRINTING?

As the filament is deposited, heat will allow the Polymer chain to ‘move’ therefore return to its ‘normal’ state; eliminating internal stress. The closer the temperature is to the materials glass transition temperature, the better. Most high quality 3D Printers are equipped with a heated bed and a ‘heat retention chamber’ which can help prevent drafts and retain the heat produced from the bed. This ambient temperature will work effectively to minimize warping for small and medium prints however it is not controlled nor is it hot enough to print medium parts with high infil or large parts with near-zero warping.

To print these parts with near-zero warping, a 3D Printer with controlled chamber heating like the INTAMSYS FUNMAT HT is required. Two active heating components maintain a controlled internal chamber temperature (up to 90°C). As the electronics are also exposed to this ambient temperature, it is important high quality and industrial grade components are used, as is the case for the FUNMAT HT. Through maintaining a high chamber temperature we have been able to achieve completely solid medium sized PC prints with absolutely near-zero warping.

Warning: Adding active heating to any standard Desktop 3D Printer will likely result in permanent damage to the printer, all electronics and product materials must be tested and rated for performance in the chambers high temperatures. This is one of the reasons most 3D printers don't have active heating.

So - how well did it work? Fantastic:

Leave a comment