22 IDEX v3

$14,900.00

Hylo™

$156,000.00

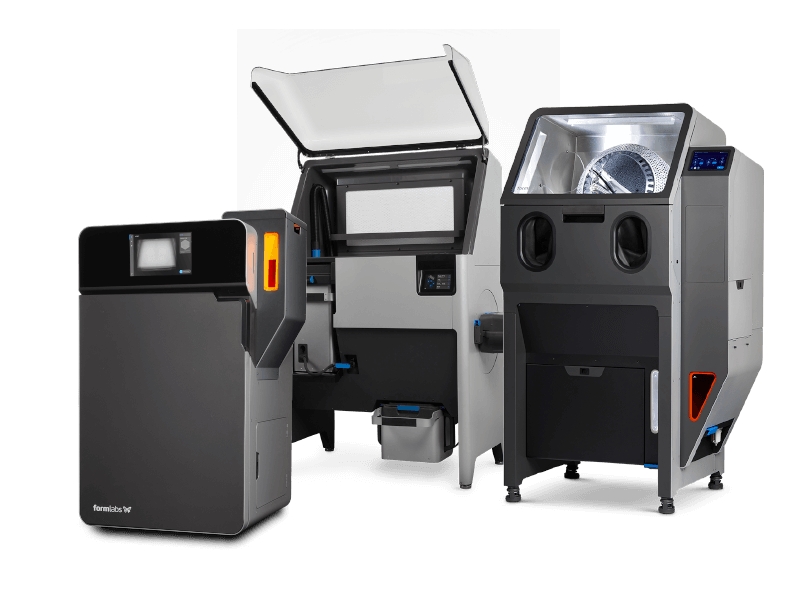

Fuse 1+ 30W Starter Package

$24,999.00

Form 4 Complete Package

$5,849.00

Form 4L Complete Package

$20,399.00

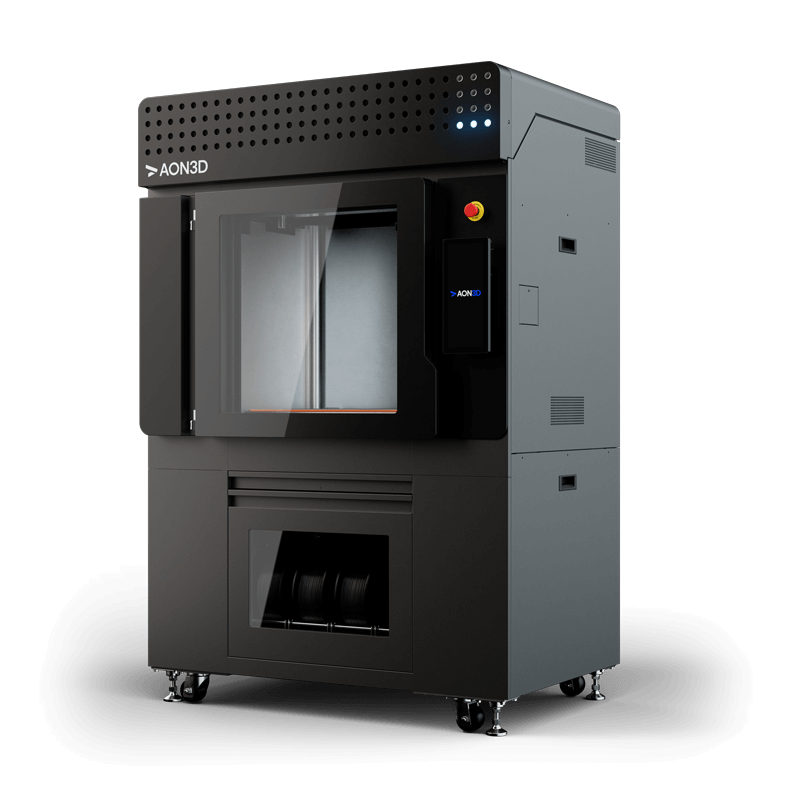

AON M2+ (CE)

$59,400.00

Fuse Sift

$9,999.00

Fuse Blast

$10,999.00

22 IDEX R&D 3D Scanner Bundle

$18,899.00–$25,900.00

Fuse 1+ 30W Standard Package

$39,084.00

Fuse 1+ 30W Production Package

$150,437.00

Fuse 1+ 30W Production Fleet Package

$564,825.00

Fuse 1+ 30W Complete Package

$54,241.00

Form 4 Basic Package

$3,499.00

Form 4 Premium Package

$10,249.00

Form 4 Printer

$3,157.00

Form 4B Basic Medical Package

$6,960.00

Form 4B Complete Medical Package

$9,227.00

Form 4B Premium Medical Package

$12,899.00

Form 4B Printer

$4,967.00

Form 4BL Basic Package

$14,399.00

Form 4BL Complete Package

$22,899.00

Form 4BL Premium Package

$38,799.00

Form 4BL Printer

$11,405.00

Form 4L Basic Package

$9,999.00

Form 4L Premium Package

$33,799.00

Form 4L Printer

$8,904.00

Form Cure L

$4,500.00

Form Cure

$750.00

Form Wash L (2nd Generation)

$4,500.00

Form Wash (2nd Generation)

$699.00

Fuse 1 Starter Package

$10,999.00