PEEK 3D Printing

More and more companies look to 3D Printing for lean manufacturing and prototyping. High-temperature thermoplastics like PEEK and PEI are superb filament choices.

HOW did these materials develop?

WHAT caused advanced plastics to transform into 3D filaments?

Is This Science fiction? 3D Printing technologies and materials have recently become public options, as opposed to previously a figment of our imagination.

Brief History of PEEK

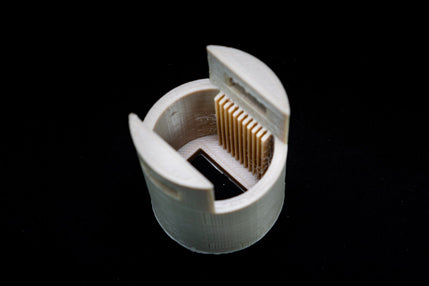

PEEK plastic was developed in the 1980s by Victrex and has expanded since the 1990s, via other chemical firms. Formulating PEEK into filament for 3D printing was an important and creative innovation. PEEK 3D Printing is possible because integral heating elements are used. These are fully-enclosed, temperature-controlled printers from companies like Intamsys.

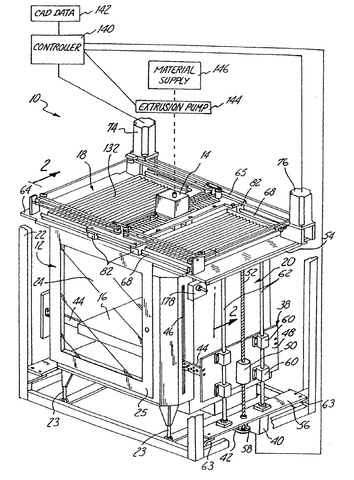

This enclosure technology was originally patented by 3D Printing company Stratasys in the early 1990s. Their US Patent 6722872 protects designs of fully-enclosed, temperature-controlled “FDM” devices.

What is FDM 3D Printing?

“Fused Deposition Modeling” refers to melting filament, which is deposited in layers that fuse together during cooling. FDM as an additive manufacturing technique was also patented by Stratasys, in the late 1990s. Their two patents were immensely important to the rise of PEEK use and other high-temperature thermoplastics. But when Stratasys’ FDM patent expired in 2009, other companies and individuals entered the market to create 3D printers.

PEEK Printing - Status Today

Most 3D Printers are FDM-based, including PEEK-capable printers. Patent 6722872 registers temperature-controlled FDM machines, but it expires in several years. Current PEEK-capable printers exist, because the patent protects only fully-enclosed printers with printing elements on the exterior. This important distinction was explored by companies like Intamsys, to manufacture new machines capable of printing other recently available high-temperature, advanced thermoplastics.

How New Are These Filaments?

An Internet search for PEEK or Polyether Ether Ketone reveals PEEK in powder, pellet, or raw block form, used for manufacturing since the 1980s. However, knowledge about PEEK as an extruded filament is undocumented, because Stratasys’ patents have prevented using 3D Printers capable of handling high-temperature thermoplastic.

Good News!

- Vision Miner is on the cutting edge of this new technology, where few US distributors of PEEK-capable printers even exist.

- Vision Miner staff spend all their efforts serving industries.

- Vision Miner explores PEEK, PEI, and other high-performance plastics first-hand as printing substances.

- Vision Miner staff work directly with customers over-the-phone and in-person.

- Vision Miner staff perform tests on many dozens of PEEK projects.

- Vision Miner is committed to discover how best to handle and harness PEEK as an evolving high-performance thermoplastic. Let us help you!

Vision Miner customer service and support for Intamsys’ Funmat printer line is founded on direct experience in PEEK 3D Printing, among only a handful of companies worldwide.

Generally, PEI is referred to as ULTEM™. This can be ULTEM™ 1010, ULTEM™ 9085, or a variety of other grades of PEI. ULTEM™ resin is created by SABIC and is a trademark of SABIC or it's affiliates or subsidiaries.

Leave a comment